Environmental simulation

Plastics are subject to a variety of environmental influences, such as temperatures, chemicals or sunlight, throughout their entire service life. These influence their performance, their service life and their functionality.

In order to prevent premature failure, we examine the various environmental influences in advance.

Our accredited environmental simulation laboratory offers a variety of standardized and individual tests.

In our accredited laboratory we carry out solar simulation, weathering test, climate test and temperature test. We support our customers in series monitoring, initial sample testing, testing and in the event of damage.

Several xenon chambers, climatic chambers, temperature shock chambers and salt spray chambers are available in our plastics laboratory for processing customer orders.

Range of services: Temperature shock tests for the rapid transfer of test specimens from a lower test temperature to an upper test temperature

Climate tests to simulate changing climatic conditions

Xenon tests for time-accelerated laboratory weathering to simulate damage caused by moisture, full-spectrum sunlight, and high temperatures.

Color measurement to determine the color and gloss effect before and after exposure

Emission measurement as well as the determination of odor behavior

outdoor exposure

Temperature and climate test

Your product is exposed to changing climatic conditions that can occur during its product life? We simulate the influences that can change service life, functionality and properties.

weathering

Weather resistance and durability are in most cases a basic requirement for products and materials that are used outdoors. We offer Florida/Arizona outdoor exposure, UV exposure testing, or cyclic exposure testing.

Solar simulation

Yellowing, fading, clouding or cracking can cause damage both outdoors and indoors. With our xenon test chamber, we can perform time-accelerated laboratory weathering to simulate damage caused by moisture, full-spectrum sunlight, and high temperatures.

emission measurement

In addition to determining the odor behavior, we offer different analysis systems (e.g.: LC-MS, HS-GC-MS & thermal desorption GC-MS) to identify individual substances and to determine their emission behavior under changing environmental conditions, such as different temperatures in a climate chamber.

Seite 1 von 7

Page 1 of 7

|

|

Dynamic differential thermal analysis (DSC) according to DIN EN ISO 11357-1Methods for recording various properties, such as glass transition, phase transformations, chemical reactions, oxidation stability and heat capacity Further Informations |

NormDIN EN ISO 11357-1:2017-02 |

ContactDr. Stefan Loibl stefan.loibl@gwp.eu |

Transfer to the request |

|

|

Determination of ash according to DIN EN ISO 3451-1Method for determining the ash for a range of plastics. e.g. analysis of filler content or proportion of fibres for reinforcement. Further Informations |

Norm |

ContactDr. Stefan Loibl stefan.loibl@gwp.eu |

Transfer to the request |

|

|

Determination of the bending properties according to DIN EN ISO 178Method for determining the bending properties of rigid and semi-rigid plastics. Further Informations |

NormDIN EN ISO 178:2019-08 |

ContactKristina Trenz kristina.trenz@gwp.eu |

Transfer to the request |

|

|

Determination of Charpy impact properties according to DIN EN ISO 179-1Notched bar impact test for the determination of the Charpy impact strength of plastics. Further Informations |

NormDIN EN ISO 179-1:2010-11 |

ContactKristina Trenz kristina.trenz@gwp.eu |

Transfer to the request |

|

|

Determination of tensile properties according to DIN EN ISO 527-2Determination of the tensile deformation behaviour with determination of the tensile strength, the tensile modulus and the tensile stress/strain relationship. Further Informations |

NormDIN EN ISO 527-2:2012-06 |

ContactKristina Trenz kristina.trenz@gwp.eu |

Transfer to the request |

|

|

Cross-cut test on coatings according to DIN EN ISO 2409Test method for estimating the resistance of a coating to separation from the substrate. Further Informations |

NormDIN EN ISO 2409:2020-12 |

ContactMax Diedering vertrieb@gwp.eu |

Transfer to the request |

|

|

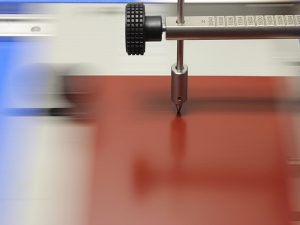

Determination of resistance to scratching with a linear lifting device according to DIN EN ISO 21546Method for determining the settling behaviour of coating materials. Further Informations |

NormDIN EN ISO 21546:2021-02 |

ContactDr. Ulrike Rantzsch ulrike.rantzsch@gwp.eu |

Transfer to the request |

|

|

Determination of the hardness of coatings by testing with pencils according to ISO 15184Method for determining the coating hardness by pushing pencils. Further Informations |

NormISO 15184:2020-01 |

ContactDr. Ulrike Rantzsch ulrike.rantzsch@gwp.eu |

Transfer to the request |

|

|

Colour fastness tests – Colour fastness to rubbing according to DIN EN ISO 105-X12Test method for determining the resistance of the colour of textiles. Further Informations |

NormDIN EN ISO 105-X12:2016-11 |

ContactDr. Ulrike Rantzsch ulrike.rantzsch@gwp.eu |

Transfer to the request |

|

|

Determination of the gloss value according to DIN EN ISO 2813Method for determining the gloss value of coatings at 20°, 60° or 85° Further Informations |

NormDIN EN ISO 2813:2015-02 |

ContactDr. Ulrike Rantzsch ulrike.rantzsch@gwp.eu |

Transfer to the request |